The Deacon Parking Garage

SSRG completed a comprehensive renovation to the existing Deaconess parking garage at University of Cincinnati. Expected increase in use and traffic to the antiquated structure demanded extensive structural repairs and modifications.

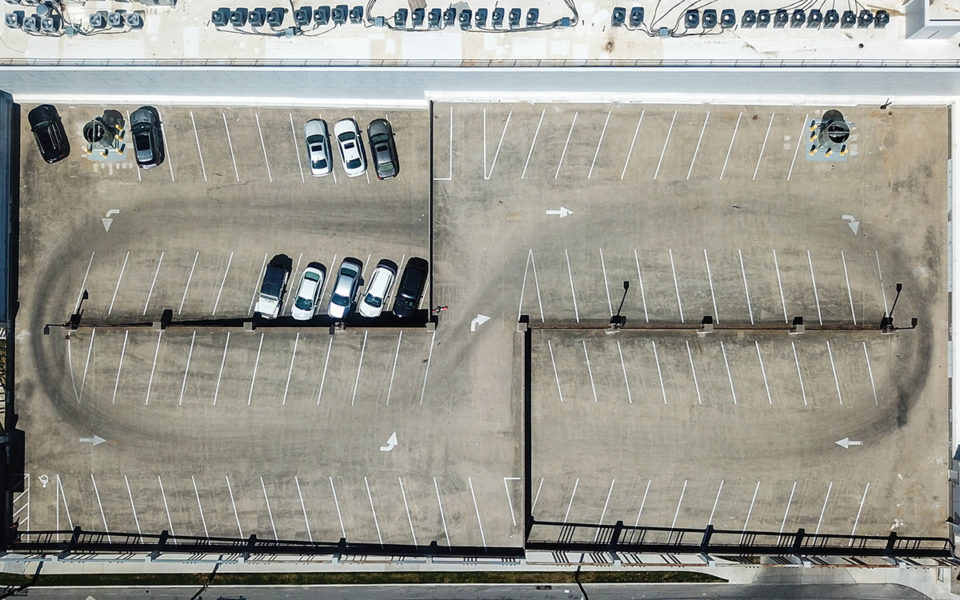

The Deacon Garage is comprised of 240,000 SF with 680 parking spots across seven levels.

The garage is from the former Deaconess Hospital in Cincinnati, Ohio which closed its doors in 2010. Since then, the five-acre site has been redeveloped into a mixed-use residential called The Deacon. It includes retail, restaurants, office and hotel, with a substantial amount of structure constructed around the existing garage.

The garage project was completed simultaneously with the construction of the mixed-use Deacon. The parking garage remained open throughout the project to allow the General Contractor access to the adjacent construction site.

Learn more about our experience in the Infrastructure sector.

The problem

This project involved extensive structural repairs and modifications to prepare the building for an anticipated increase in traffic. The project needed to be phased carefully to ensure accessibility throughout the lifespan of the project. An adjacent site was undergoing construction of an apartment building, and the general contractor required access by way of the parking garage. Early on in the project, the crew discovered broken post-tension cables throughout the deck.

Learn more about our Specialty Steel Repair and Strengthening services.

The fix

A comprehensive restoration to such a large concrete structure involves many details. This scope included:

- Reworking the post-tension cables to accommodate new load paths due to ventilation equipment, as well as creating large openings for ductwork.

- Extending the cast-in-place columns (their third extension!) by upwards of 14’ to accommodate new structural steel frames for future vision screening.

- Strengthening the precast spandrel beams and cutting them down in height to create flush deck-to-deck egress at each level between the garage and the new adjacent residential tower.

- Complete replacement of double tee stem heads.

- Repairing and strengthening the cast-in-place header beam at the central crossover.

- Complete replacement of 7 levels of concrete landings, stair pans and concrete treads.

To deal with the broken post-tension cables, the team installed shoring underneath to support the deck. After that, they replaced the cables inside the existing sheathe.

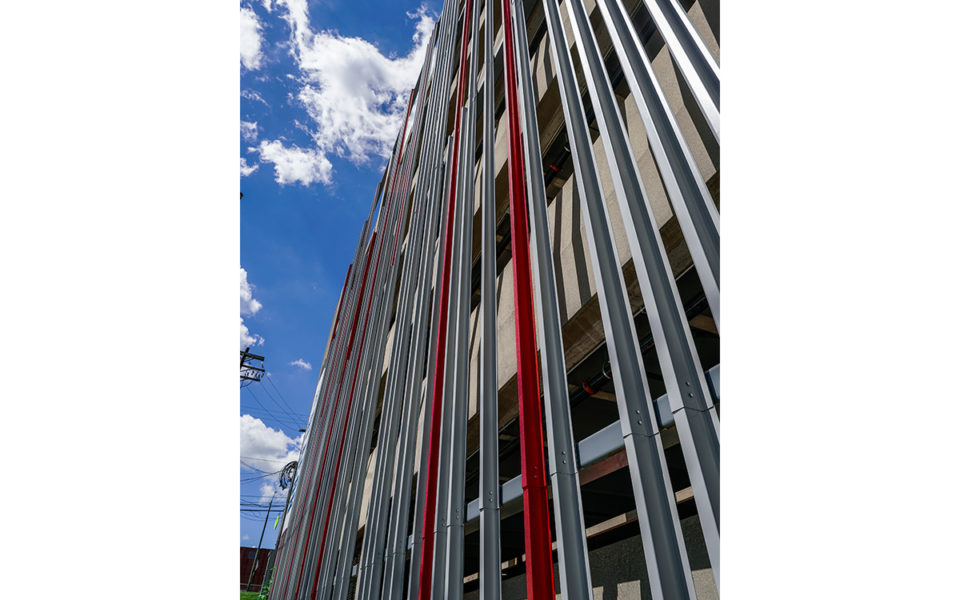

In order to construct the garage screen wall, the crew extended 12 concrete columns on top of the garage. Then, the crew used a concrete crane hopper to pour column extensions in preparation for the architectural screen. The steel screen is steel and covers all open sides of the garage. It uses more than 15,000 linear feet of vertical steel members, which are spaced apart for aesthetics.

The team used an electric chain hoist to hold the 22’ long, 660-pound beams in place. Next, they utilized a swing stage to pull the beams up and put them in place. The team installed an average of four steel members each day. Value engineering processes allowed the team to save $200,000 on the screen and to reduce the total cost from $800,000 to $600,000. The team painted the final product red and grey to match the University of Cincinnati’s school colors.

Standing Strong for Years to Come

In the end, the project included more than 2,700 SF of concrete repairs. Other scope included:

- New post tension deck opening

- Precast deck opening

- Structural steel repair

- New structural steel

- Traffic coating and line striping

- New CMU masonry and concrete stair pans installed. The North side stair tower was completely removed with a new CMU wall and new structural steel stairs installed. In the South side stair tower, the concrete stair pans and steel structure were removed and replaced.

The Deacon opened by fall semester of 2019. Only 200 steps to campus, it is the closest off-campus private student housing at the University of Cincinnati. The covered parking garage provides students with safety and, thanks to the extensive repairs, will be in use for many years to come.

Great guys on the job. They went above and beyond to do the work right.